This Literature Review answered the three primary questions: What Assistive Device to make?, Which Design Methodology to implement?

and finally, Which 3D-Printing technique to use? by reviewing a wide range of scholarly articles, case studies, technical advancements

and research papers on Cognitive Impairments, Design Methodologies, and 3D-printing technologies respectively.

Observations:

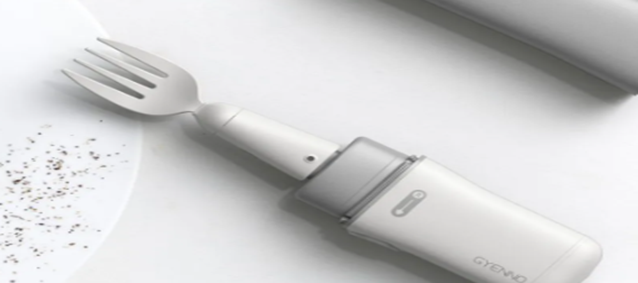

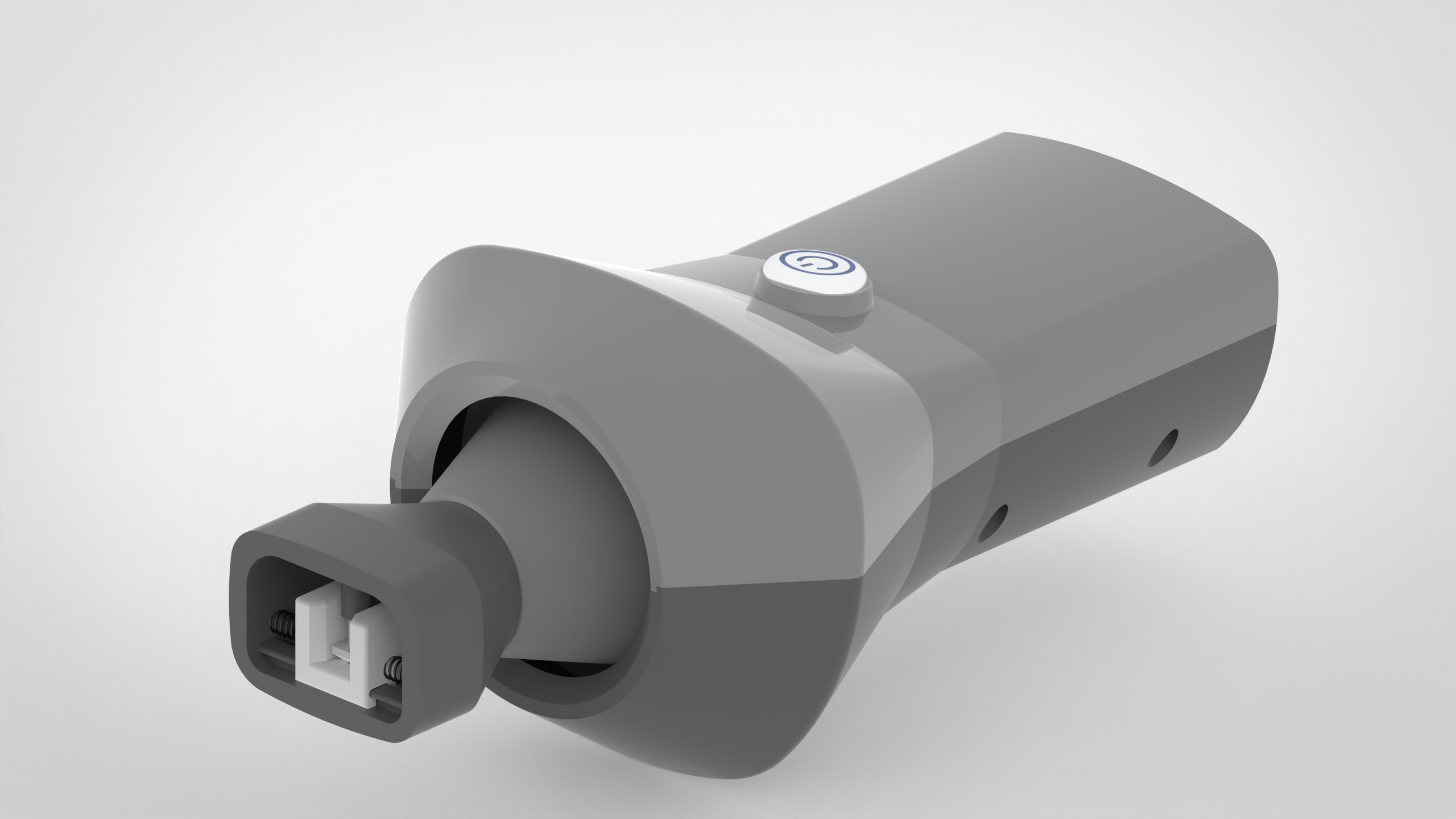

- Cognitive Impairments: Essential Tremor (ET) is the most common side effect of cognitive impairment, specifically from mild stage to dementia. This discovery prompted the choice of Essential Tremor as the target area due to its enormous market and prevalence of over a million people suffering alone in the UK. Therefore, the creation of Assistive Device that is especially made for people with Essential Tremors (ET) was then made.

- Design Methodologies: After evaluating various design methodologies like Participatory Design Methodology, Inclusive Design Methodology, and User-Centric Design Methodology. It was concluded that The User-Centric Design Methodology will be used as the design approach in this scenario. As will put the end-user’s usability, preferences, and needs first, resulting in a solution that effectively meets their needs.

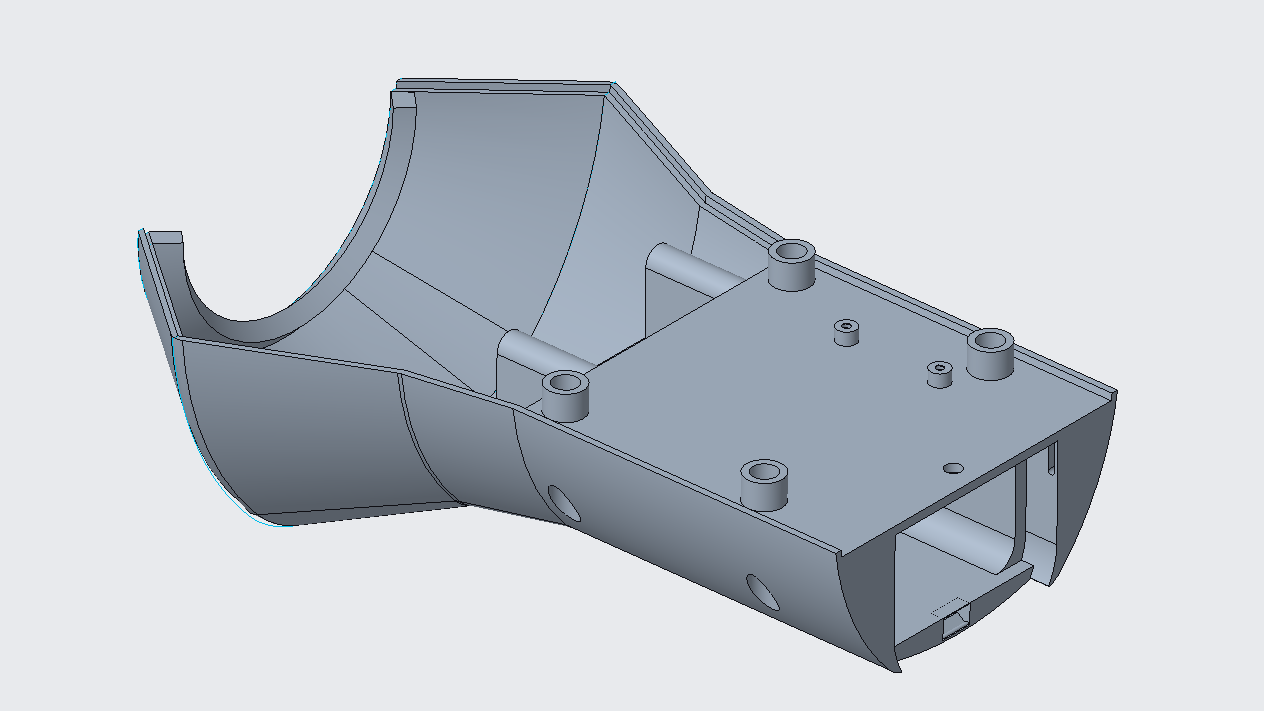

- 3D-Printing: After weighing the pros and cons of each 3D Printing Technique available it was found that the Selective Laser Sintering (SLS) was a suitable manufacturing process due to its high precision, exceptional durability, and capacity to create complex shapes.

Conclusion:

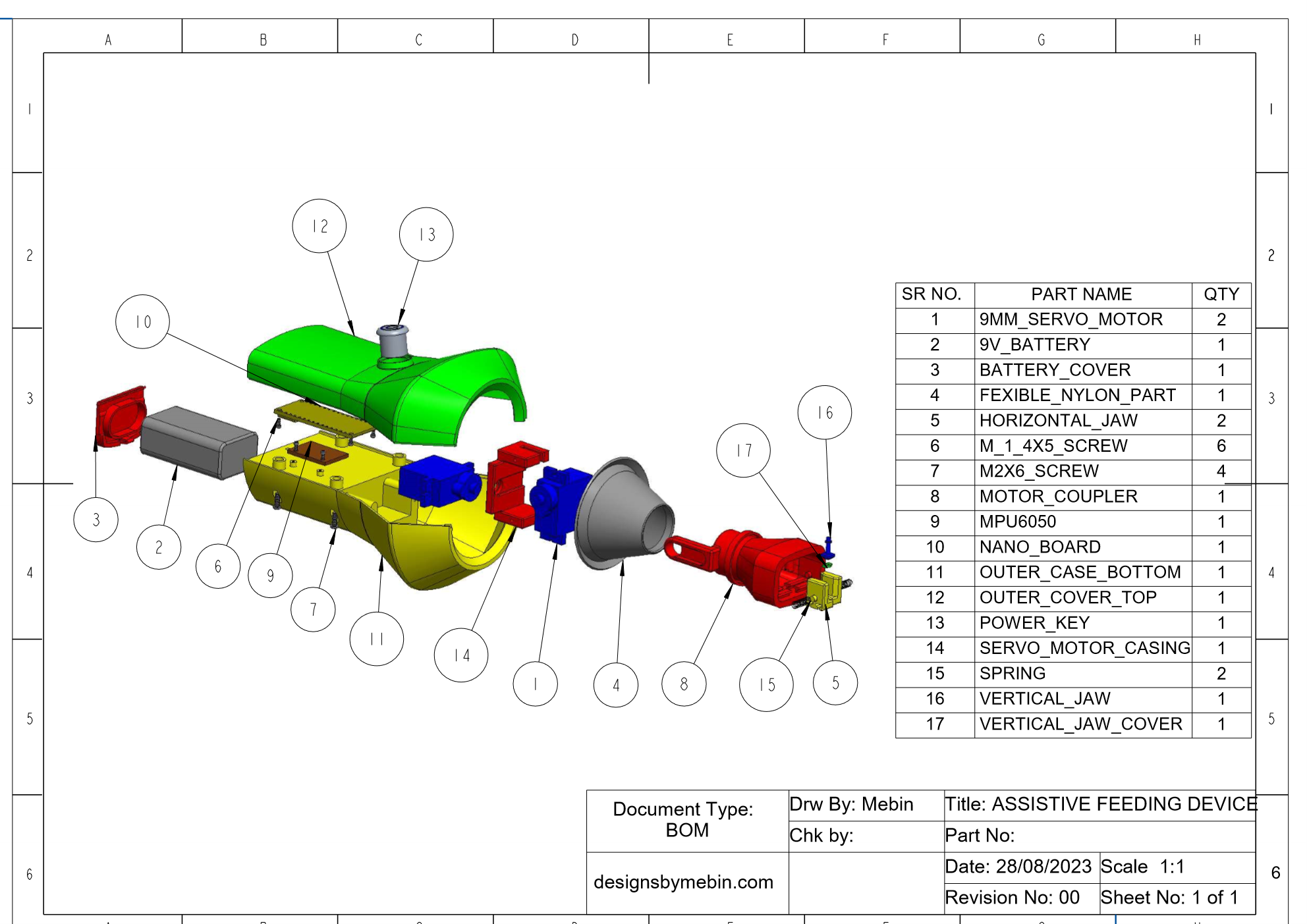

Finally, the conclusion drawn from the Literature review to design and develop

an Assistive Device for Essential Tremors (ET) using User-Centric Design Methodology and manufactured by Selective Laser Sintering (SLS) 3D-Printing.